The toughest prefinished edge insulation for your foundation.

The toughest prefinished edge insulation for your foundation.

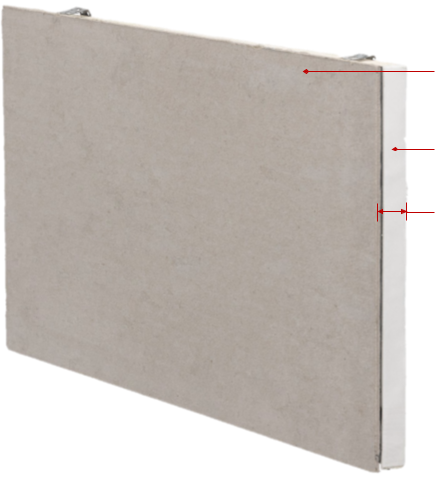

Fibrocement outer shell. Your EdgeBoard™ does not fear your lawn trimmer succeeding where other insulation boards fail. Note: Two coats of acrylic paint are recommended to preserve product performance.

Pressure sensitive adhesive tape. Aesthetics matter. All joints are sealed to prevent the cement slurry from reaching and staining the outer face of your EdgeBoard™.

Reduced thickness. Compatible for flush installation with standard 140 mm timber framing, the EdgeBoard™ may also be used in combination with 90 mm timber framing. Please refer to the technical details provided at the bottom of this page for more information.

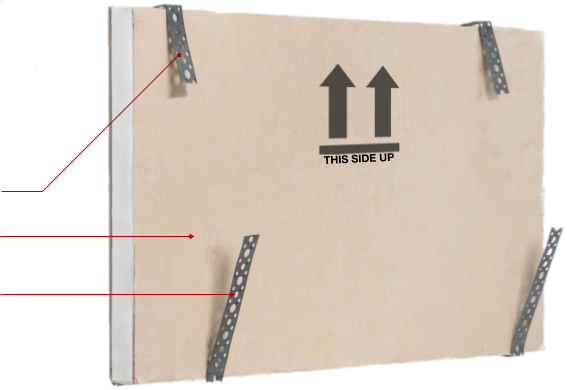

Upper foldable clips. A series of 304 stainless-steel clips are provided to secure your EdgeBoard™ onto your foundation.

Closed cell phenolic foam core. Thanks to first-class insulation materials your EdgeBoard™ delivers the highest thermal insulation in a reduced thickness.

Lower foldable clips. A series of 304 stainless-steel clips are provided to secure your EdgeBoard™ onto your foundation.

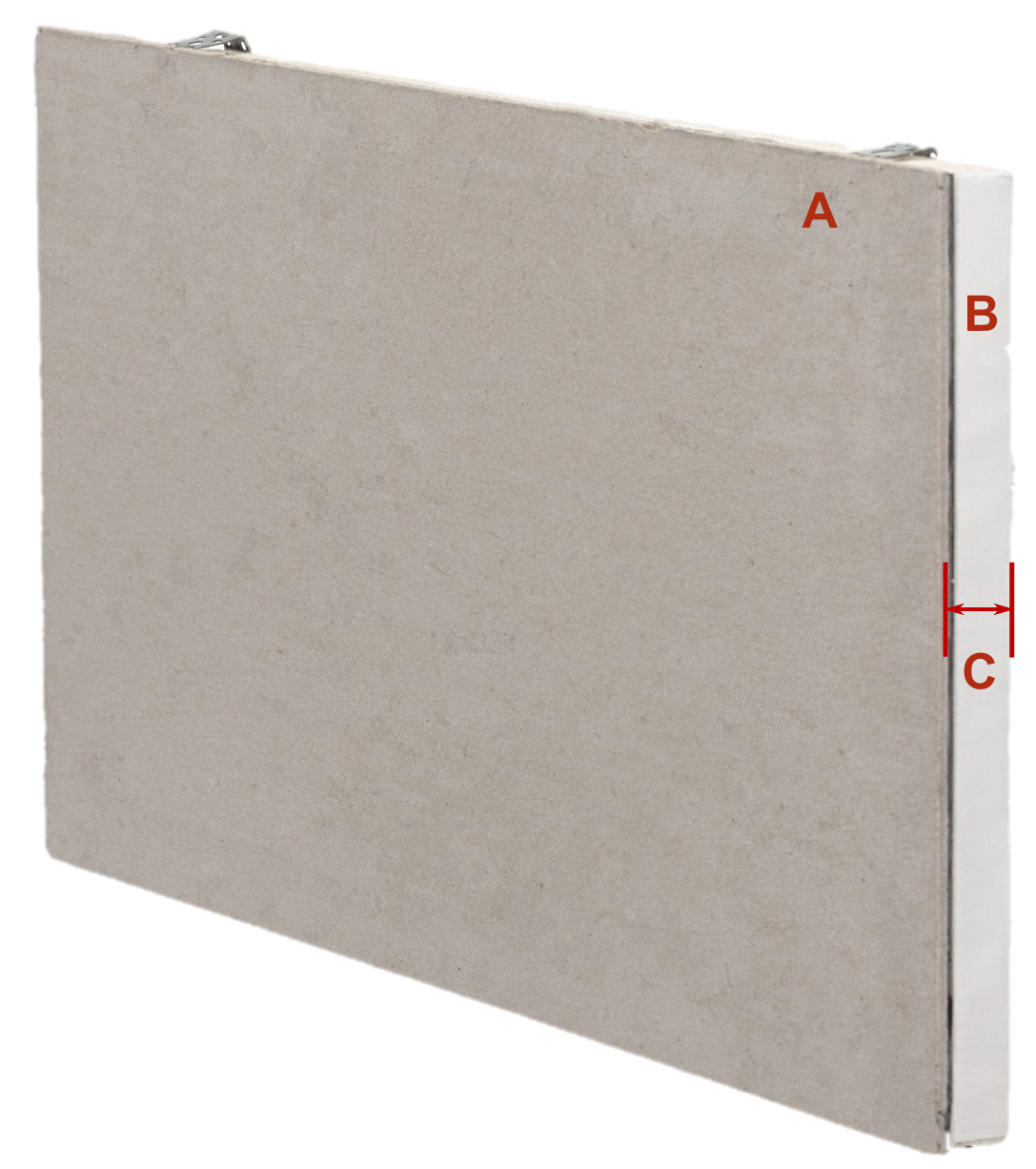

Fibrocement outer shell. Your EdgeBoard™ does not fear your lawn trimmer succeeding where other insulation boards fail. Note: Two coats of acrylic paint are recommended to preserve product performance.

Pressure sensitive adhesive tape. Aesthetics matter. All joints are sealed to prevent the cement slurry from reaching and staining the outer face of your EdgeBoard™.

Reduced thickness. Compatible for flush installation with standard 140 mm timber framing, the EdgeBoard™ may also be used in combination with 90 mm timber framing. Please refer to the technical details provided at the bottom of this page for more information.

Upper foldable clips. A series of 304 stainless-steel clips are provided to secure your EdgeBoard™ onto your foundation.

Closed cell phenolic foam core. Thanks to first-class insulation materials your EdgeBoard™ delivers the highest thermal insulation in a reduced thickness.

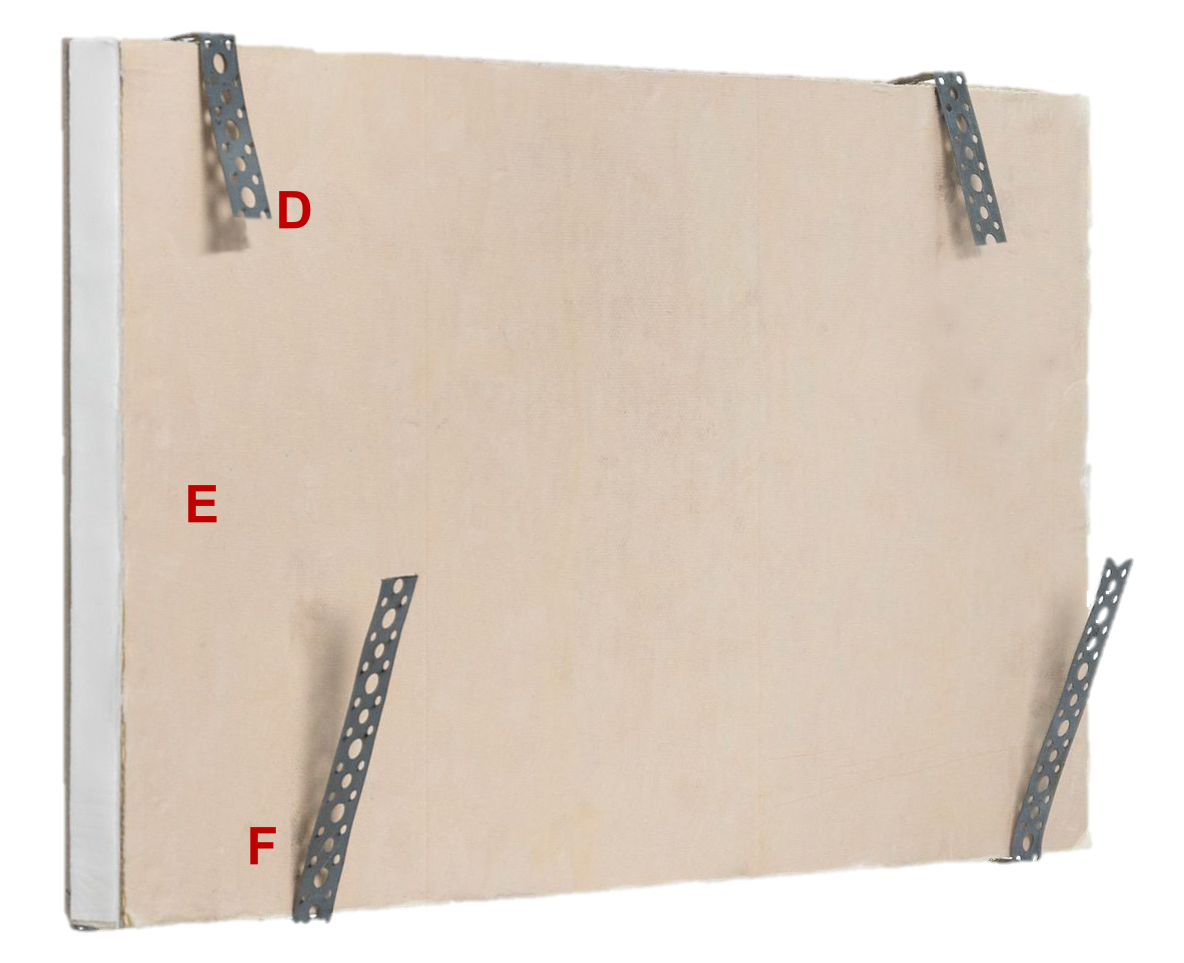

Lower foldable clips. A series of 304 stainless-steel clips are provided to secure your EdgeBoard™ onto your foundation.

1. Make sure that the board corner bead is clean and dry before you join the boards with the pre-installed double-sided adhesive tape. IMPORTANT: Ensure that the upper part of the EdgeBoard™ remains approx. 2 mm below the finished floor level all times.

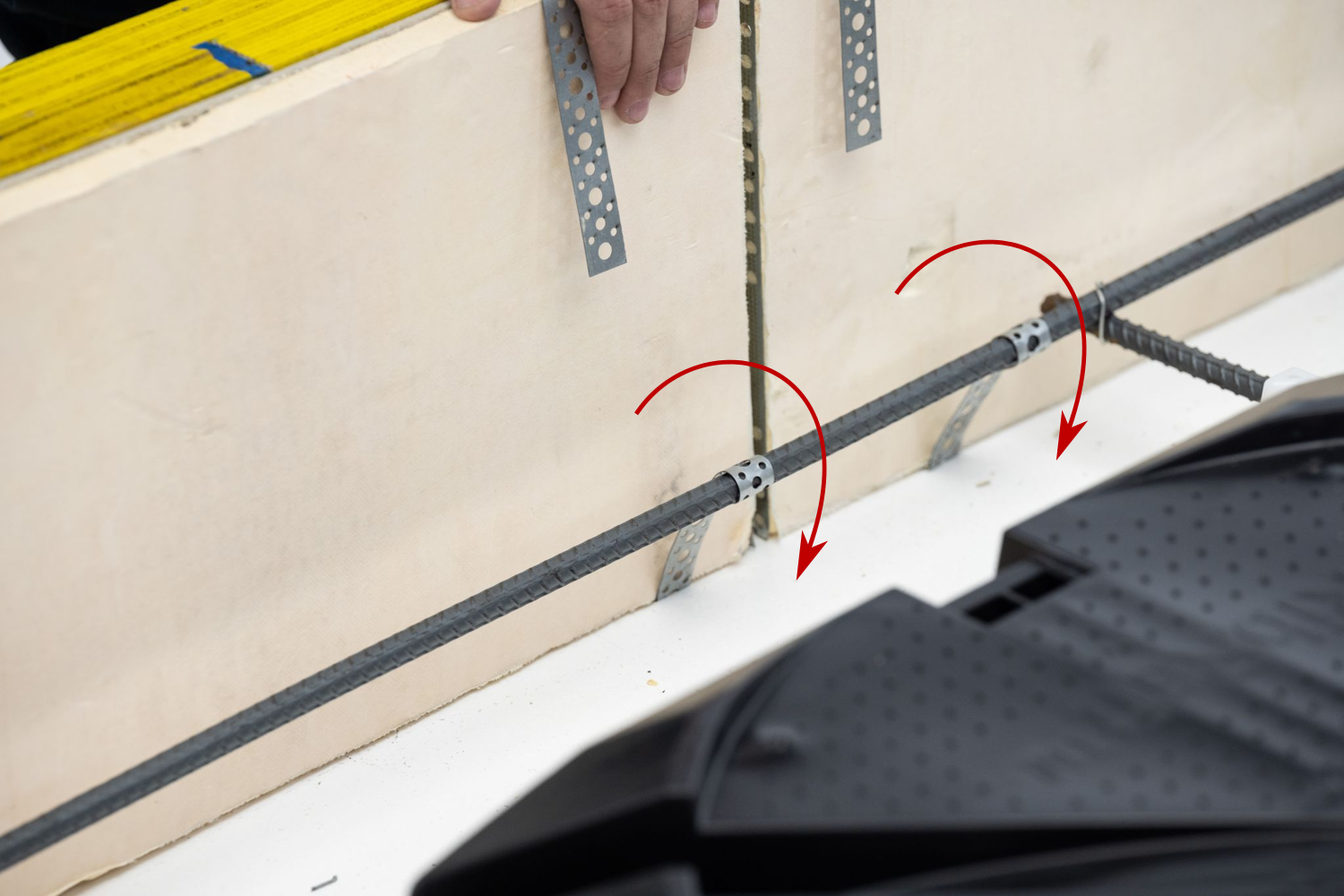

2. Secure the boards by folding the lower clips around the reinforcing bars of the foundation.

3. For superior stability during construction, temporary fix the board to the boxing along the length with self-tapping screws (1 screw every meter).

4. Fold up the upper clips. IMPORTANT: Do NOT attach the upper clips to the reinforcing steel of the foundation.

5. At outer corners, cut off a strip of insulation layer. (No cuts are required at inner corners).

6. Position and connect the boards together. At foundation corners, we recommend fixing each end of the boards to the boxing with self-tapping screws (see point 3).

1. Make sure that the board corner bead is clean and dry before you join the boards with the pre-installed double-sided adhesive tape. IMPORTANT: Ensure that the upper part of the EdgeBoard™ remains approx. 2 mm below the finished floor level all times.

2. Secure the boards by folding the lower clips around the reinforcing bars of the foundation.

3. For superior stability during construction, temporary fix the board to the boxing along the length with self-tapping screws (1 screw every meter).

4. Fold up the upper clips. IMPORTANT: Do NOT attach the upper clips to the reinforcing steel of the foundation.

5. At outer corners, cut off a strip of insulation layer. (No cuts are required at inner corners).

6. Position and connect the boards together. At foundation corners, we recommend fixing each end of the boards to the boxing with self-tapping screws (see point 3).